"Industrial Projects services from the Idea establishment to final product outcome.

MECHWEBB team ensure for all Solutions."

Our Expertises

Steel Sector

Chemical Sector

Commercial Complex Sector

FMCG Sector

Projects & Services

we provide solutions and support to different industries by analyzing their operations, condition, costing & work practices for improving production, quality and reduces maintenance cost. Target the optimizing solutions to industry by working on innovative ideas, engineering solutions and well planned project management.

What We Provide

Responsive Team Members

Team Members understand the work culture and our internal upgradation process provide the best industrial solutions.

Market analysis

we upgrade our self as per market change & preparing project reports by aiming future requirement to control cost of project or services.

Different industries brains

we collaborate right industries experience person & mix team with other industries experience Person also, so that innovative ideas come on desk.

best in class

This innovative idea convert the "Mechwebb" as a complete solution provider for industrial projects & services work.

Industrial Services

hvac system design

fab.- structure/pipe/ eqp

insulation- hot & cold

eqp.- erection/ commissioning

engineering support

project management

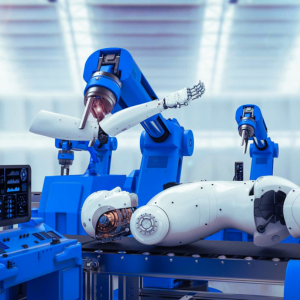

industrial automation

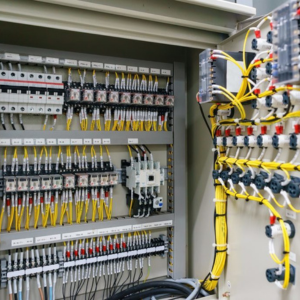

electrical engineering

Industrial Projects

Yeast Plant Project

“Yeast” manufacturing unit project report prepared by the expert of yeast experience person, have the capability of design the units as per the best utilization of resources. The project report generate with the consideration of current market scenario, market size, future demand, analysis of CAGR for next 10 years trend, statics and forecast. the comprehensive report cover all the technical details like plant & machinery drawings, technical aspects, mass flow calculation, raw materials and product specification, aspect time of plant execution, rOI etc.

The “YEAST PROJECT REPORT” develops as per the “INVESTMENT PLAN” and preparing the completion timeline of project cover the best analysis by Industry Expert. The whole reports are created by Expert Consultant and they have vast experience of “Yeast” Manufacturing Unit.

“Yeast” is a living unicellular microorganism until it is destroyed by heat or other physical or chemical means of about one hundredth of a millimeter in size and can therefore not be observed with a naked eye. Yeasts are a group of unicellular microorganisms most of which belong to the fungi division of Ascomycota and Fungi.

The scientific name of baker’s yeast is “Saccharomyces Cerevisiae”.

Yeast, the most common one being “S. cerevisiae”, is used in baking as a leavening agent, where it converts the food/fermentable sugars present in dough into the gas carbon dioxide. This causes the dough to expand or rise as gas forms pockets or bubbles. When the dough is baked, the yeast dies and the air pockets “set”, giving the baked product a soft and spongy texture. When yeast is used for making bread, it is mixed with flour, salt, and warm water or milk. The dough is kneaded until it is smooth, and then left to rise, sometimes until it has doubled in size. The dough is then shaped into loaves. Some bread doughs are knocked back after one rising and left to rise again (this is called dough proofing) and then baked. A longer rising time gives a better flavor, but the yeast can fail to raise the bread in the final stages if it is left for too long initially.

The industrial production and commercial use of yeasts started at the end of the 19th century after their identification and isolation by Pasteur. Today, the scientific knowledge and technology allow the isolation, construction and industrial production of yeast strains with specific properties to satisfy the demands of the baking and fermentation industry (beer, wine, cider and distillates). Food grade yeasts are also used as sources of high nutritional value proteins, enzymes and vitamins, with applications in the health food industry as nutritional supplements, as food additives, conditioners and flavouring agents, for the production of microbiology media, as well as livestock feeds. Yeasts are included in starter cultures, for the production of specific types of fermented foods like cheese, bread, sourdoughs, fermented meat and vegetable products, vinegar, etc.

The significance of yeasts in food technology as well as in human nutrition, as alternative sources of protein to cover the demands in a world of low agricultural production and rapidly increasing population, makes the production of food grade yeasts extremely important. A large part of the earth’s population is malnourished, due to poverty and inadequate distribution of food. Scientists are concerned whether the food supply can keep up with the pace of the world population increase, with the increasing demands for energy, the ratio of land area required for global food supply or production of bioenergy, the availability of raw materials, as well as maintenance of wild biodiversity. Therefore, the production of microbial biomass for food consumption is a main concern for the industry and the scientific community.

Strach Plant Project

“Strach” manufacturing unit project report prepared by the expert of Strach experience person, have the capability of design the units as per the best utilization of resources. The project report generates with the consideration of current market scenario, market size, future demand, analysis of CAGR for next 10 years trend, statics and forecast. the comprehensive report cover all the technical details like plant & machinery drawings, technical aspects, mass flow calculation, raw materials and product specification, aspect time of plant execution, rOI etc.

The “STRACH PROJECT REPORT” develops as per the “INVESTMENT PLAN” and preparing the completion timeline of project cover the best analysis by Industry Expert. The whole reports are created by Expert Consultant and they have vast experience of “Yeast” Manufacturing Unit.

“Starch” production is an isolation of Starch from plant sources. It takes place in starch plants. Starch industry is a part of food processing which is using starch as a starting material for production of starch derivatives, hydrolysates, dextrins.

At first, the raw material for the preparation of the starch was wheat. Currently main starch sources are:

- Maize (in America, China and Europe) – 70%,

- Potatoes (in Europe) – 12%,

- Wheat – 8% (in Europe and Australia),

- Tapioca – 9% (South East Asia and South America),

- Rice, Sorghum and Other – 1%.

Steel Plant Project

“Steel” manufacturing unit project report prepared by the expert of Steel industries experience person, have the capability of design the units as per the best utilization of resources. The project report generate with the consideration of current market scenario, market size, future demand, analysis of CAGR for next 10 years trend, statics and forecast. the comprehensive report cover all the technical details like plant & machinery drawings, technical aspects, mass flow calculation, raw materials and product specification, aspect time of plant execution, rOI etc.

The “STEEL PROJECT REPORT- HOT ROLLING MILL” develops as per the “INVESTMENT PLAN” and preparing the completion timeline of project cover the best analysis by Industry Expert. The whole reports are created by Expert Consultant and they have vast experience of “Yeast” Manufacturing Unit.

“Steel” Industry, specially Hot Rolling Product i.e. TMT, The advent of thermo mechanically treated (TMT) steel bars has heralded a new era of economy in the construction industry in India. Round plain steel ruled over this industry up to sixties while Tor steel took over the scene in seventies and maintained its supremacy till nineties. 1997 and 1998 has now seen an extensive use of TMT steel and corrosion resistance steel thereby ushering in greater economy and longer life for RCC structures.

TMT bars are widely used in general purpose concrete reinforcement structures, bridges and flyovers, dams, thermal and hydel power plants, industrial structures, high-rise buildings, underground platforms in metro railway and rapid transport system. TMT Bars is an acronym for thermo-mechanical treatment. Thermo Mechanically Treated (TMT) bars are manufactured using the Quenching & Tempering (Q & T) technology. A TMT bar gets its strength properties from quenching and tempering. No mechanical treatment is involved in TMT Bars. In TMT bars, the carbon content can be restricted to 0.2% to attain weldability and at the same time no strength is lost on this account. The joints can be welded by ordinary electrodes and no extra precautions are required. Another advantage of TMT bars is their tough surface providing high yield strength and a soft core providing excellent ductility. Strength, weldability and ductility are such properties which declare TMT steel highly economical and safe for use.